Metautek’s journey in addressing software challenges for metal fabrication manufacturers

Discover how a major metal manufacturer achieved success with custom solutions

In today’s dynamic digital landscape, software has evolved into a pivotal component across diverse industries

However, in the world of metal fabrication and distribution, a paradox emerges: although so-called “tablet” or off-the-shelf software applications have the potential to dramatically improve productivity and efficiency, their integration into this sector presents specific challenges that require meticulous thought and strategic anticipation. Addressing these metal fabrication software challenges is crucial for successful implementation and optimization, ensuring that companies can fully leverage technological advancements to achieve their goals.

From modest custom manufacturers to expansive metal distribution enterprises, businesses increasingly depend on software solutions to enhance operational efficiency and bolster their competitive edge.

Software plays a crucial role in the metal fabrication and distribution sector, automating various processes and improving the overall workflow.

From inventory management to order processing, from part cutting to optimized loading order on delivery trailers, software systems enable companies to track and monitor their operations, reducing manual errors and optimizing resource allocation.

In addition, advanced analysis tools help identify trends and patterns, enabling organizations to make data-driven decisions to improve profitability.

Subscribe to receive our exclusive updates directly to your email.

Although software offers many advantages, its implementation in the metal industry is not without obstacles.

Firstly, metal manufacturers and distributors are often faced with complex supply chains, involving multiple stakeholders and intricate logistics.

Implementing a software solution that meets these specific requirements can be difficult, as off-the-shelf options (tablet software) may not take sufficient account of the subtleties of the industry, or even the subtleties that emerge in each company.

In addition, legacy systems and obsolete technologies are common in the metalworking industry, making the transition to modern software solutions a daunting task.

Manufacturers and distributors are often overloaded, and more often than not mobilize their in-house manpower to improve or implement machines or robots on the factory floor, rather than dedicating time to improving their management software or the range of software used on a daily basis.

Integrating new software with an existing infrastructure requires careful planning, often unavailable resource allocation, and employee training that is all too often neglected. If this transition is poorly executed, it can lead to disruptions in daily operations and delays in fulfilling customer orders.

The manufacturer or distributor ends up with a constellation of software that :

Discover how a major metal manufacturer achieved success with custom solutions

To overcome the challenges posed by software implementation, metal manufacturers and distributors need to consider several factors:

Investing in software tailored to the specific needs of the metalworking industry is essential. By choosing specialized software, companies can address the specific challenges faced by the sector, such as supply chain complexity and inventory management. We don’t need to reinvent the wheel with bespoke, but rather use bespoke to go further with existing solutions and, above all, interconnect them.

A one-size-fits-all approach won’t work for metal fabricators and distributors. Software solutions need to be customizable to fit existing processes and integrate seamlessly with legacy systems. This ensures minimal disruption during implementation and enables a smooth transition. Make sure that the specific solutions you choose have native interconnection capability (often referred to API) to enable systems to be interconnected together, and above all add functionality that will be missing as your business evolves.

Employee buy-in is essential for successful software implementation. Providing comprehensive training programs and ongoing support will enable staff to effectively use the software’s features and maximize its benefits. Experienced trainers can guide employees through the learning curve, ensuring smooth incorporation of the software into day-to-day operations. This is usually the weakest point of the operation. To put it in perspective, would you install a new $1,000,000 machine in your factory without giving your team any training? Well, that’s what happens all too often with software. We install it, and since we don’t physically see people scratching their heads using it on a day-to-day basis, we take it for granted that they’ll guess how to use it properly. The result: software is often misused, or underused, greatly affecting your competitiveness.

Metal fabricators and distributors face a major problem when it comes to interconnecting the various software packages selected with their existing systems.

The software available on the market is often not fully compatible with existing infrastructures, making it difficult to integrate different systems seamlessly. This incompatibility can lead to delays in operations and loss of efficiency.

This is where a good custom software development partner comes in. By working with a partner experienced in custom software development, metal fabricators and distributors can seamlessly interconnect their existing systems and add the missing and crucial functionality to fully automate their operations.

The aim is not to replace good software already in place, but to complement it and make it more efficient by interconnecting it with other systems and adding customized functionality. A good custom software development partner will work closely with you to understand your specific needs and create tailor-made software solutions that meet those requirements.

The big issue we’re currently observing is that there are many “tablet” software options in the market to address various “micro” needs, but nothing that generally encompasses all operations.

The metal fabrication and distribution industry places crucial importance on software to improve efficiency and productivity. However, integrating these software solutions faces unique obstacles, including complex supply chains and legacy systems.

Out-of-the-box software can also lack company-specific functionality. To solve these problems, it’s imperative to invest in metallurgy-specific software, customize and integrate existing software solutions, and provide adequate training and support for employees.

Interconnection and customization of existing systems represent major challenges for manufacturers and distributors of metal products. Off-the-shelf software solutions are often not compatible with existing infrastructures, and cannot be fully adapted to specific industry needs.

By working with a partner specialized in technology solutions, companies can overcome these obstacles and effectively automate their operations. Implementing customized software development ensures compatibility and maximizes efficiency.

For more insights on navigating the paradox of custom software development in the manufacturing industry, check out our article Custom Software Development for Manufacturing Industry: Navigating the Paradox.

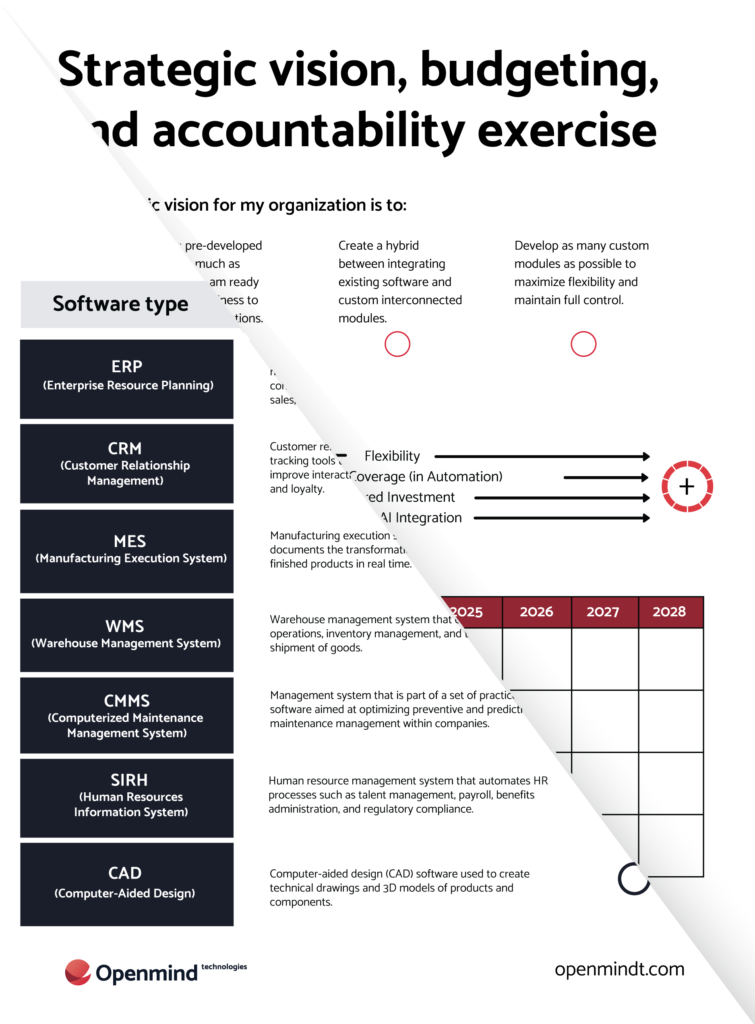

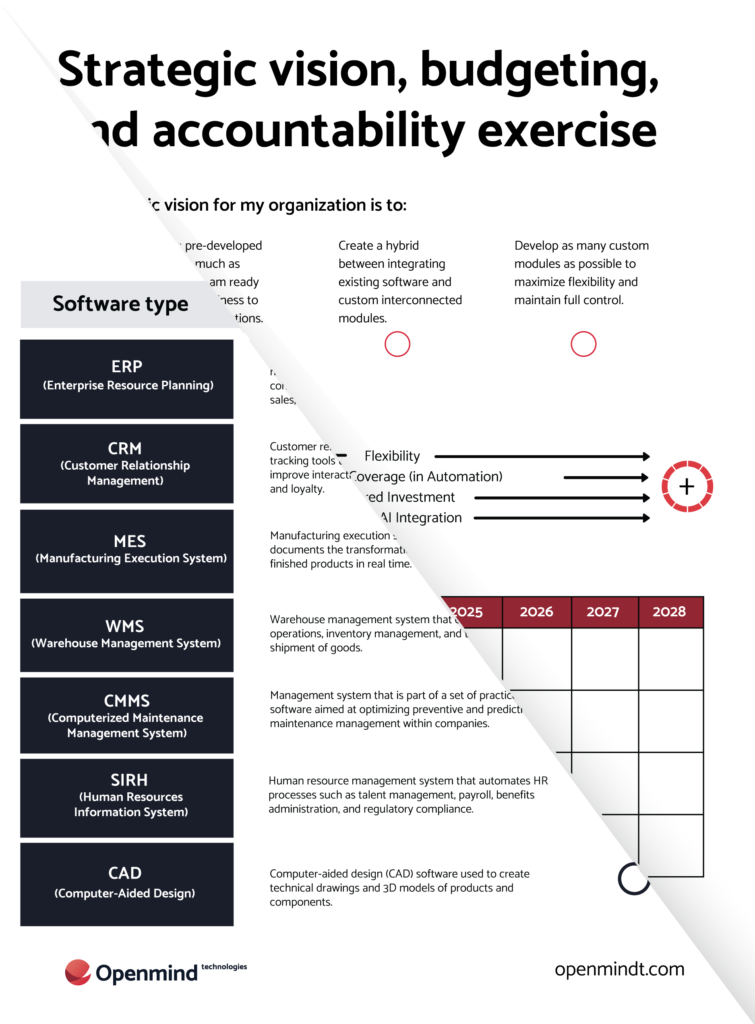

Download our Technological Maturity Self-Assessment & Strategic Vision Exercise tools to assess your software ecosystem profile and to plan for future growth.

Tell us more about your needs so that we can better route your project to our specific SWAT team.

1

During the brainstorming phase, we work with you to identify potential solutions to your business challenges to generate the technology response that aligns with your business objectives.

2

Through our requirements gathering process, we work closely with you to define and prioritize your needs, ensuring that our solutions are tailored to meet your specific requirements.

3

This phase marks the beginning of our partnership. We’ll finalize the project plan and establish clear communication channels to ensure a smooth and successful project execution.